Humidity in the insulation system, together with the decomposition of the paper insulation, has a substantial impact on the ageing process of transformers and, consequently, on the service life of the transformer.

A high humidity content in the insulation causes a decrease in the dielectricity of the insulating oil and an acceleration of the ageing process of the cellulose insulation. As a consequence:

- transformers in good condition fail prematurely

- the service life is considerably reduced

- operational safety is compromised

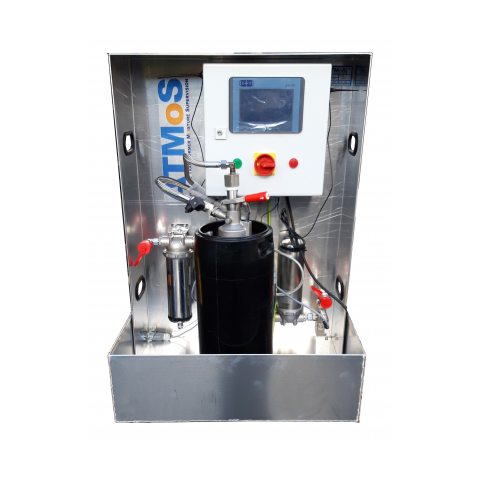

ATMoS (Automatic Transformer Moisture Supervision) provides continuous material savings and sustainable supervision of transformer dewatering and humidity.

ATMoS is a filter system that removes humidity from the insulation system (oil and cellulose) during regular operation. Additional particle filters remove dirt and suspended materials from the insulation oil. For this purpose, the age of service, the manufacturing company and even the installation site are of no particular importance, ATMoS is adaptable to the existing operating and environmental realities.

Concept

The insulating oil is led through cartridges containing special filter granulate - the moisture is removed and bound at a molecular level. The effect is immediately measurable. Conventional dewatering of the oil at this point can be considered complete.

However, most humidity is located in the cellulose insulation and diffuses into the oil very slowly.

ATMoS is in operation during regular transformer operation and is designed for long-term service. The insulating oil is constantly dried. It generates a water concentration gradient between the paper insulation and the oil, causing the water to diffuse and remove the oil accordingly. The filter granulate binds the water molecules and thus makes re-wetting impossible.

Installation and operation are carried out during regular transformer operation - no switching off or dismantling of components is necessary. Using an intuitive control system, ATMoS can be conveniently operated remotely; reference values can be set and controlled very easily, without the need for time-consuming and expensive user training.

Industrial particle filters remove suspended particles and dirt while gases remain in the oil: Dissolved Gas Analysis (DGA) can still be conducted to assess the condition of the transformer and detect possible faults at an early stage.

Control and monitoring are carried out via a PLC, accessible via Ethernet, W-LAN or GSM connection from fixed or mobile devices such as tablets or smartphones.

The operator can set target humidity values individually for the oil and cellulose insulation. The PLC supervises the achievement and maintenance of these values.

The portable version of the ATMoS allows the operator to simply move the system from one transformer to another.