The LFH system is used for fast and efficient drying of transformers on site. The system is used for drying transformers after on-site repairs, special transport conditions or can be used for drying prior to commissioning. This solution saves up to 1/3 of the time compared to a conventional treatment.

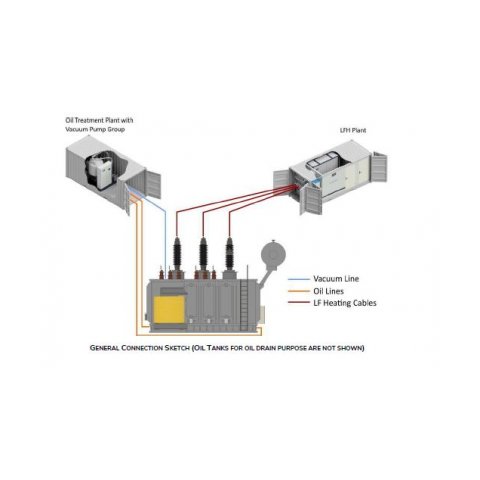

The DASOTEC Mobile LFH and OTP treatment system is used as a low-frequency heating system for transformers/reactors. The LFH system will perform the entire drying process. Interaction with the OTP oil treatment system and its vacuum system can be performed fully automatically or by confirming that the required operation on the oil treatment system has been performed manually. The current generated by the LFH System that will heat the windings can be modulated according to the transformer's rating plate data or the limits set by the manufacturer.

For optimum drying, the transformer must be heated at the same time as the vacuum is applied (as during the Vapor Phase process). With the combination of low frequency heating (LFH) and hot oil spraying or hot oil circulation, this can also be achieved on-site. The low-frequency voltage is necessary to reduce the voltage applied to the transformer when it is under vacuum. The reason is that the breakdown voltage of the insulation system is much lower under vacuum than under atmospheric pressure. This is also known as Paschen's law.

Your requests

For any queries, please contact us at:

info_at_dasotec.it

In order to be able to provide a quick response on specific test requests, following the general information is very helpful:

- Number of equipment to be tested

- Equipment characteristics / nameplate data

- Pictures or technical drawings

- Place and date of test

- Reason for test (e.g. FAT/SAT or diagnostic test)

- Test standard

After assessing your request, we will contact you to clarify all details regarding site tests.