STP-BRR / Bladder Rupture Relay; membrane rupture sensor for power transformer conservator

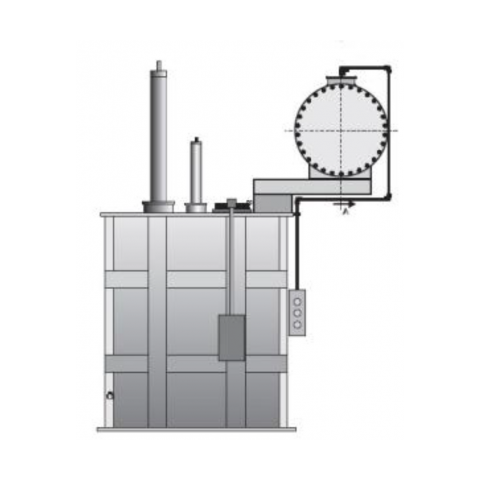

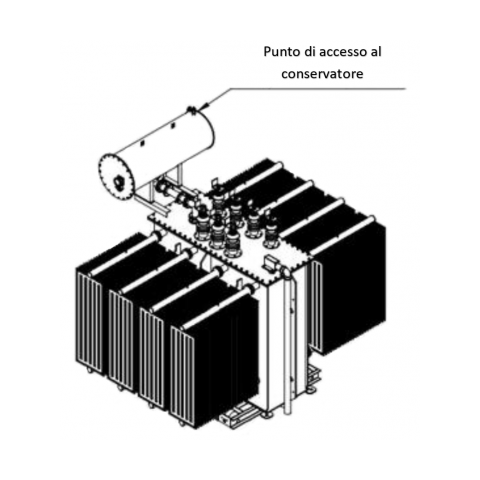

The STP-BRR / Bladder Rupture Relay sensor is a device capable of detecting the rupture of the membrane of the Pronal STP (Sèparateur Transformateur Puissance) conservator used in oil conservators on power transformers and hydraulic systems.

STP-BRR consists of an optical sensor to be mounted inside the rubber membrane (on the airside), an interface box, a control unit located in the transformer control cabinet, and the cable.

The sensor is equipped with a polysulfone capsule containing an emitter LED and a drive circuit. The control unit has a reversible contact and two LEDs, one to signal membrane rupture and another to signal the switch-on status.

The operation of STP-BRR is based on the principle of light reflection. When no oil is present, the light produced by the emission LED is completely reflected back into the membrane from the surface of the capsule, and captured by the optical receiver. If oil covers the capsule, the reflection effect of its surface changes. The rupture causes part of the emitted light to be lost in the oil and the amount of light reaching the optical receiver to be reduced. This change in light reflection causes the connection circuits to become unbalanced and the signal contact to operate.

The STP Membrane

Pronal STP membranes are installed inside the oil conservator of power transformers to protect the oil from external contamination.

When the oil level varies, they independently inflate with atmospheric pressure to compensate for the change in oil volume. Thus, the dielectric oil is never in contact with outside air and is protected against contamination.

The quality of the dielectric oil is a key parameter for the reliability of the power transformer. The STP membrane is a first prevention system. The STP-BRR sensor is an increasingly popular protection system.

The greatest advantages of these systems are that they avoid transformer maintenance, oil treatment and guarantee general transformer protection.

Ordering Information

Bladder Rupture Relay Kit includes:

- 1 optical sensor

- 1 control unit

- 1 Signal connection box

- 1 cable, 5 meters (10 & 15 m upon request)

Simple as described below:

- an optical sensor that must be mounted inside the membrane during its installation in the conservator or even when it is already installed

- a signal connection box whose main purpose is to allow the passage of the sensor signal from inside the conservator to the control unit

- a control unit located in the transformer's control cabinet equipped with 2 LEDs, one to signal a rupture of the membrane and another to signal the switch-on status.

| Features | Range/Description |

| Power Supply | From 38 to 265 V DC / V AC - 50/60 Hz |

| Power Consumption | ≤ 3 W |

| Operative Temperature: Relay | - 10 °C ... + 70 °C |

| Operative Temperature: Sensor | - 20 °C ... + 100 °C |

| Protection Class | IP 20 |

| Wire Size | 0,3 mm2 ... 2,5 mm2 22 ... 12 AWG |

| Monitoring | DIN rail 35 mm |

| Input | |

| 1 STP-BRR Sensor | |

| Output | |

1 Reversible Contact | |

| Max. Switching Power | 60 W /62,5 VA |

| Max. Switching Voltage | 220 V DC / 250 V AC (non inductive) |

| Max. Switching Current | 2 A |

| LED | |

| Green | On - Connected |

| Red | STP/BRR (rupture of the air chamber) |

| Sensor Features | Range/Description |

| Operating Temperature | -40 ... +100 °C |

| Protectin Class | IP 67 |

| Cable | 4 x 0,5 mm2, 200 °C |

Electrical Transient Immunity (IEC 60255-4 / 60255-6) | |

First-Cycle Peak Value | 2,5 kV |

| Frequency | 1,1 MHz |

| Frequency Repetition Time | 2 seconds, 400 peaks/s |

| 50% Decay | 5 cycles |

| Voltage Pulse (IEC 60255-5) | |

| Wave Form | 1,2/50 μseg |

| Amplitude and Energy | 5 kV |

| Nr. of Pulses | 3 negative and 3 positive, 5 seconds intervals |

| Applied Voltage (IEC 60255-5) | |

| Industrial Frequency Dielectric Test | 2 kV, 60 Hz 1 min to earth |