T401; Real-time transformer monitoring device

T401

- Rugged, Compact Design, Plug and Play

- Up to 8 Configurable Analog Inputs

- Up to 8 Configurable Analog Outputs

- Up to 8 Programmable relays, Form - C

- Best in EMI class , ESD Immunity

- Easy to use software for visualization and configuration

- Transformer Analytics: Winding Hot Spot Calculation, Insulation Life Assessment

- Calculation of winding temperature from CT load current and Top Oil Temperature - the unit, therefore, acts as a thermal image - WTI

Reliable and robust monitoring system for a wide range of analog and digital sensors with advanced transformer health analysis, suitable for industrial and energy utility applications.

Product Features

T401 is a multi-channel datalogger system for a wide range of analog and digital sensors/signals.

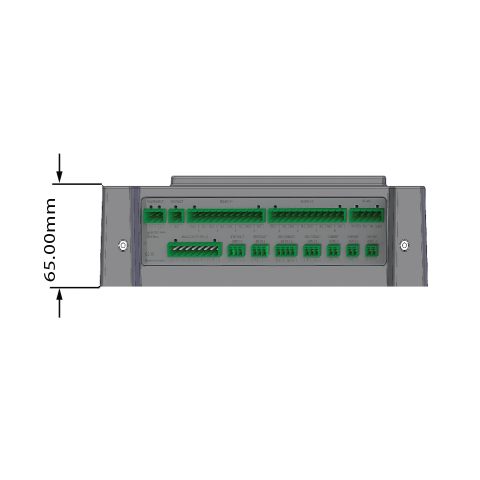

T401 comes with the flexibility to fit up to 8 analog/digital inputs, 8 analog outputs and 8 relays. All inputs channels can be connected with the most available sensors and configured by a user-friendly software application.

The unit also comes with local displays (LED) for real-time values of analog inputs.

T401 is designed to operate reliably in very high voltage environments/substations.

T401 is designed to collect data and easily interface with existing systems through serial communications such as RS-485 or Gigabit Optical Ethernet.

The device is equipped with Rugged Connect software designed for test platform or industrial process monitoring integration needs. The device allows the integration of data from multiple test platforms. Plug and Play functionality allows you to swap sensors without calibration.

The supplier has a specialised team to customise fiber optic sensor specifications, monitor configuration and software integration.

Applications

- Power transformer monitoring

- Distribution transformer monitoring

- Resin transformer monitoring

- Motor/generator monitoring

- Data center battery monitoring

- Industrial process control and monitoring

Benefits

- Fully configurable modular inputs

- Robust housing, data logging

- Advanced analysis/calculations

- Relay for control functionality, i.e., cooling control

- Support for different protocols for integration with existing systems

- Customisable to customer-specific applications

- Suitable for OEM applications

- Local display for real-time values

| TECHNICAL DATA | |

Number of input channels | up to 8 |

Input channel types | Configurable from a wide range of input options, RTD, AC/DC Current, AC/DC Voltage, Potentiometer, No-load/powered contact switch |

Input channel accuracy | ± 0,5% of full-scale input range |

Input channel sample rate | 10 Hz |

Number of analog outputs | up to 8 |

Analog output types | 0-10 V / 4-20 mA configurable by user |

Max. number of relay outputs | up to 8 |

Relay output types | Form-C relays (5A), programmable by user |

Pwer supply | 24 ... 48 V DC |

Power consumption | 20 Watt |

Memory | 4 or 8 GB, Industrial Grade micro-SD, extendable to 2TB |

Logging | configurable by user; 10 years at 10 sec interval rate (8 GB) |

Serial port | RS-485 with Modbus |

Ethernet port (optional) | RJ-45 or Gigabit Optical Ethernet (Optional) |

System fault indication | 1 System Fault Relay, with Local LED light |

Operating temperature | - 40 ... 72 °C |

Humidity | 95% non condensing |

Storage temperature | -40 ... 85 °C |

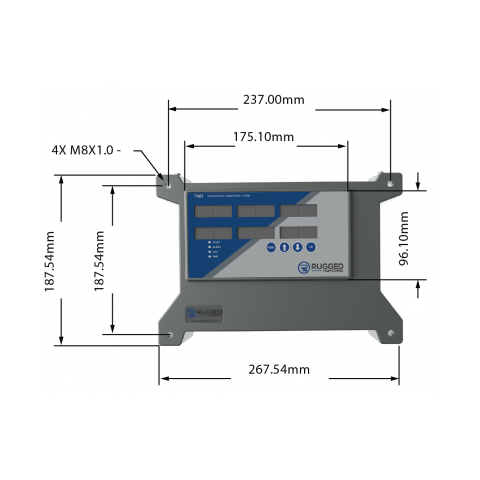

Dimensions | 26,7 cm x 7,2 cm x 18,7 cm (LxAxP) |

Protection class | IP20 |