T501; Real-time transformer monitoring device

T501

T501is a multi-channel data recording system for a wide range of analog and digital sensors/signals.

T501 can monitor the following transformer parameters:

- Transformer oil temperature

- Ambient temperature

- Load current

- Oil level indication

- Cooling system status (fans/pumps)

- Winding hot-spot temperature

- Average winding temperature

- Transformer ageing and loss of life

- Overload capacity

- Cooling control and fan bank exercise

The transformer monitoring system, T501, is designed to monitor the evaluation of essential transformer condition parameters, with the flexibility to use the following input signals/sensors:

- Up to 6 analog inputs with the combination of: RTD, potentiometer, CT, 4-20mA and VT inputs

- Up to 2 digital inputs for binary signals from transformers, e.g. fan/pump status

- Up to 24 fiber optic channels for temperature measurement of winding hot-spots

- Up to 8 programmable analog outputs (4-20mA or 0-5/10V) to send data to third-party systems

- Up to 8 relay outputs (Form C relays) to send an alarm signal to third-party systems

- Different communication options, e.g. serial (RS485), Ethernet (RJ-45) and fiber optic (SFP) ports

The T501 is a panel-mount unit that can be easily installed in the transformer control enclosure. The monitor is easily configured with the integrated software, Rugged Connect and web-client. Rugged Connect is a Windows-based software for data collection, analysis, visualisation and reporting. The T501 also comes with a web client that allows remote viewing, configuration and reporting via a web browser.

In addition, T501 can also send data to customer data loggers using the following protocols, which are supplied as an option separately with the unit:

- Serial protocols: Modbus, DNP3.0, IEC 60870-5-101

- Ethernet protocols (TCP / IP): Modbus, DNP3.0, IEC 60870-5-104, IEC61850

The T501 can also be integrated with other advanced sensors on the transformer, e.g. Dissolved Gas Analysers (DGAs), Partial Discharge Monitors (PDs), bushing monitors, and others. Integration with third-party monitoring systems can be done using standard communication protocols such as Modbus and DNP3.0.

Transformer Health Assessment

- Remote monitoring and control

- Estimated insulation lifetime

- Overload capacity

- Boiling temperature

- Humidity in insulation

- Real-time alarm and notifications

- Easy integration

Transformer Monitoring

- Oil temperature

- Winding temperature

- Load current

- OLTC on-load tap-changer position

- Liquid level

- Vessel pressure

OLTC On-Load Tap-Changer Monitoring

- Oil temperature

- Oil level

- OLTC position

- Switch motor current

- Wear contact

Direct Measurement Hot-Spot Winding

- AT, BT & MT Winding

- Nucleus hot-spot

Bushing Monitoring Integration

- Leakage current

- TanDelta

- Power factor

- Capacity

Partial Discharge Integration (PDM)

- PD amplitude

- PD discharge rate

- PD tendency

Cooling Control

- Pump/fan status

- Fan bank motor current

- Cooling efficiency

- Operation of the loading bank

Integration of Dissolved Gas Analyser (DGA)

- DGA single-gas

- MDGA multi-gas

- Humidity

Certificates

- ATEX

- Lloyds

- CE/RoHs

- EAC & GOST certificate (Russian)

Varieties

- Offshore

- Ethernet redundancy: PRP

- Enterprise monitoring software

| Power supply | Input Power Requirement | 24 - 48 V DC |

| Power Consumption | 20 Watt | |

| Analog/digital input module | Number of input channels | up to 8 channels |

| Input types | Configurable from a wide range of input options, RTD, AC/DC Current, AC/DC Voltage, Potentiometer, No-load/powered contact switch | |

| Channel accuracy | ± 0,5% full-scale input range | |

| Input Channel Sample Rate | 10 Hz | |

| Fiber optic modules | Measurement range | -80 °C ... +300 °C (cryogenic 4 °K range optional) |

| Resolution | 0,1 °C | |

| Accuracy | ± 1,0 °C (± 0,2 °C in relative temperature) | |

| Scan rate | 200 ms/channel (Optional: Faster scanning rates available) | |

| Number of channels | 2 ... 24 channels | |

| Analog output module | Number of output channels | 8 channels |

| Output channel format | 4 - 20 mA o 0 - 5 V DC / 0 - 10 V DC (Configurable for any measured/calculated value) | |

| Output relay module | Number of outout channels | 8 Form C-Relay (5 A) |

| Programmable by user | Yes, from Rugged Connect Software | |

| Data storage & configuration | Data Storage Capacity | 4 or 8 GB, Industrial Grade micro-SD, extendable to 2TB |

| Logging rate | User Configurable, 1 sec interval on USB | |

| System fault indication | 1 System Fault Relay, with Local LED light | |

| Config port | USB (to use with Rugged connect Windows software) | |

| Communication | Serial communication | 1 RS-485 (RS-232 optional converter) |

| CANBUS communication | 1 CANBUS port | |

| Ethernet communication | 2 Ethernet Ports, configurable to RJ-45 or SFP (Gigabit Optical) | |

| Redundancy | Support PRP Redundancy | |

| Supported protocol | Modbus, DNP 3.0, IEC 60870-104, IEC 61850, CANBUS Other protocols provided on request | |

| EMC type testing | Conducted & Radiated Emissions | ICES-003 (2016), CISPR32 (2015), CISPR11 (2015) |

| ESD and EM Field Immunity | IEC 61000-4-2, C37.90-3, IEC 61000-4-3, C37.90.2 | |

| Fast Transient & Surge Immunity | IEC 61000-4-4, IEC 61000-4-5, C37.90.2 | |

| Magnetic Field Immunity | IEC 61000-4-8, IEC 61000-4-10 | |

| Immunity from Conducted Disturbances | IEC 6000-4-6, IEC 61000-4-16 | |

| Ripple, Dips & Damped Oscillatory | IEC 61000-4-17, IEC 61000-4-18, IEC61000-4-29 | |

| Safety | IEC 60255-26 Certificate & CE | |

| Environmental & mechanical conditions | Operating temperature | -40 °C ... +72 °C |

| Operating humidity | 95% non condensing | |

| Storage temperature | -40 °C ... +85°C | |

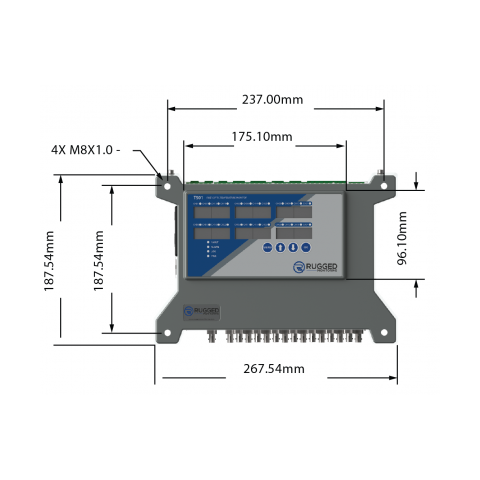

| Dimensions | W 26,7 cm x H 7,2 cm x D 18,7 cm | |

| Weight | App. 1.5 to 2.0 Kg. (based on number of configuration) | |

| Protection class | IP20 |